+91-98782-46000

+91-98150-73454

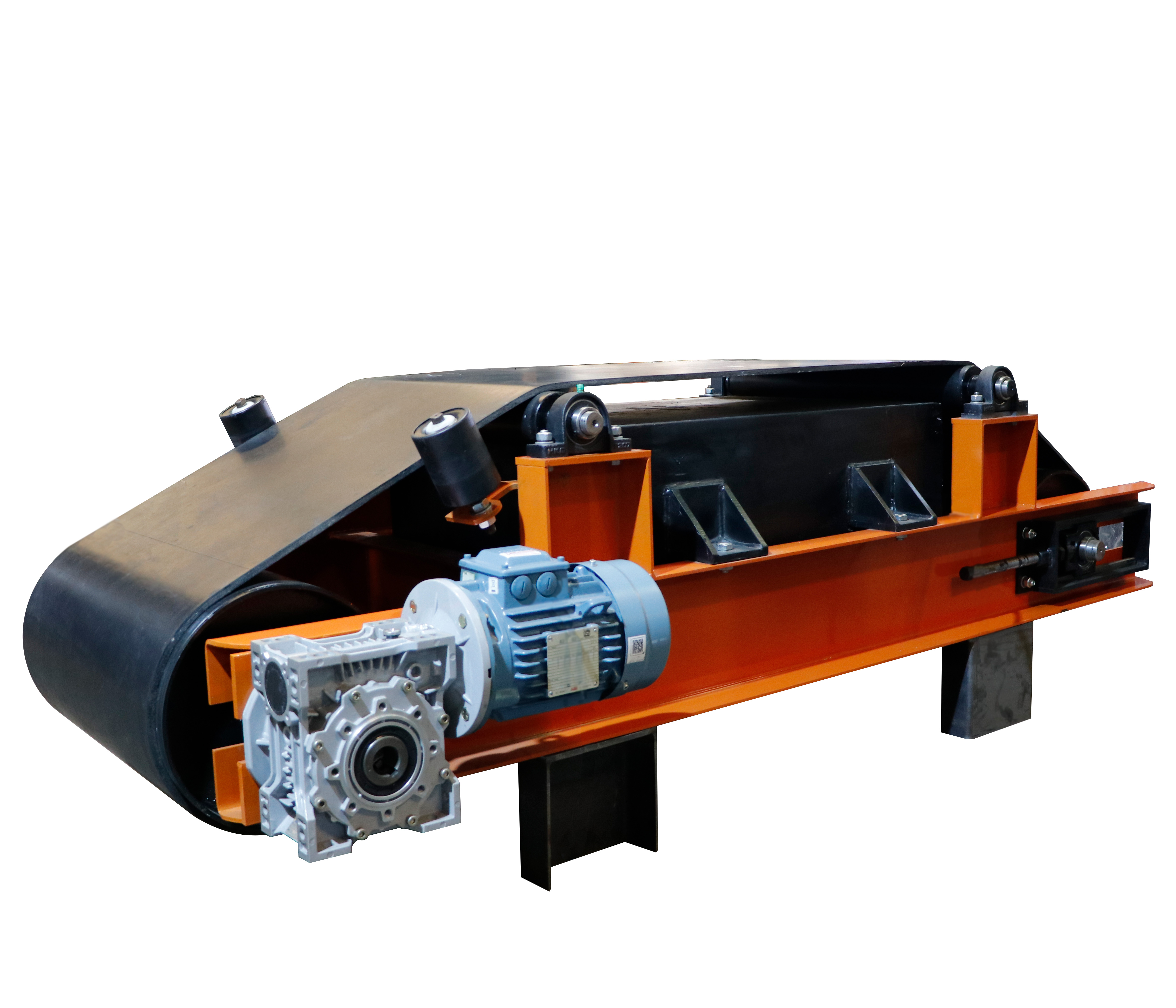

Overband Suspended Magnet are used for removing magnetic parts from non-magnetic materials in order to project crushers, mills, processing plants etc. against too much wear and damage. They serve for cleaning non-magnetic bulk goods with iron contamination, for instance cleaning of foundry sand, coal and the like. They are used for recovering magnetic material from ore, steel mill slag etc

Bhupindra Machine Manufactures offers Inline Magnetic Separators that can be installed in the feed lines, such as the outlet of elevators, screw conveyors, and more. The separators are equipped with flanged type inlet and outlet connections, and the magnetic drum features high-intensity strontium/rare earth magnets. These separators are extensively employed in cattle feed plants, flour mills, rice mills, minerals, refractories, glass, and many other products.

Generally, Overband inline Magnetic separator are installed above conveyor belts, vibratory feeders or chutes. They pick up ferrous metal parts from the bulk goods. In most cases, the magnets can also be installed in an existing installation without much expense.

When using Cross belt Magnetic separator many factors must be considered for the various applications, and it is impossible to list them all in a brochure. Each application, each material and each kind of conveying involves different problems.

Owing to the shape (demagnetization factor), long, bar-shaped and large iron parts can be better separated than short, cube shaped bulbous and small iron parts.

The efficiency of the electro Overband Magnetic separator depends on the pole size, pole distance, field intensity in the conveyor burden, lines of the material to be separated.

Large burden depths, large lump sizes, sticky or humid material render the separation more difficult.

If you want Drum magnetic separator? contact us